Description

Add Speed and Consistency to Your Process.

The applications for inline mixers and blenders are limitless. Products requiring the highest shear levels will benefit from the SHEAR-max high shear mixer, capable of mixing and efficiently pumping product with its hybrid impeller design.

Lower shear requirements can be met with the SBI or SBH inline blenders.

No matter what the product requirements are, our team will work with you to customize the perfect solution for your application – Ampco Applied Products are extremely versatile with a wide range of customization options … and always engineered to exacting specifications.

Applications

Beverages – Energy drinks, tea, fruit juice, vegetable juice, coffee blends

Dairy – Yogurt, sour cream, ice cream mix, flavored milk, eggnog, pudding

Food – Salad dressing, salsa, hot sauce, mayonnaise, pizza sauce, ketchup and mustard

Personal Care – Toothpaste, lotion, cream, shampoo and conditioner, body wash

Thickeners – Gum, pectin, starch, gelatin

Ingredients and Additives – Aspartame, non-fat dry milk, salt, citric acid, sugar, egg powder, whey protein concentrate, calcium carbonate, honey, powder flavoring

Bio-Pharmaceutical – Cough syrup, ointment, lotion, vitamin drink, contact solution, coatings,

fertilizers, paints, herbicides, ink and dye compounds

Performance Personified in SBI Shear Blender Series.

“By using Ampco’s SBI Series blender, we got whole raw sweet potato pieces down to nearly 0% retention of a 0.023 screen in just one pass.”

Great Plains Food Processor

Ampco Applied Products offers two shear blender model series: SBH/SBI. Applications range from pharmaceutical to food, industrial to chemical … and everything in between.

These highly engineered products with critical tolerances are machined, manufactured and assembled in Glendale, Wisconsin and can be fully customized for every need. Teeth thickness, number of teeth, radius and Cartesian coordinates of the SBI blades can all be specified per customer.

For more info, contact the Pump & Valve team for full details.

All models can be customized upon request based on your specific application requirements.

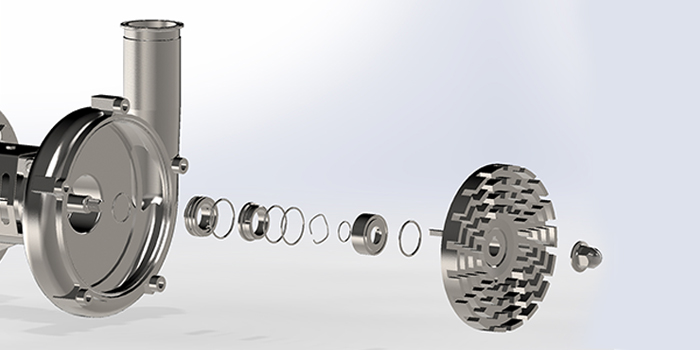

SBI Shear Pump

The SBI Pump Series pumps and blends product in a single stage. This innovative design can move product and create considerable pressure by way of a hybrid impeller.

This fine-tuned impeller design – used in combination with two rows of rectangular shear teeth – can attain amazing performance levels. As with the SBH, the SBI is based on the Ampco LF Series pump and offers multiple front loading seal options.

SBI Advantages

Customizable

Front Loading Seal Options

Easily Converted to Double Seal in the Field

304 Stainless Steel Adapter

Affordably Priced

Manufactured and Assembled in the U.S.A.

SBI Features

Low – Medium Shear Levels

Combination Integrated Impeller and Dynamic Shear Teeth

Pump and Blend in a Single Stage

Cast and Machined

304 Stainless Steel Adapter

Dynamically Balanced Impeller

316L Stainless Steel Shaft

SBI Performance Overview

Models: 7

Max Flow Rate: 510 GPM / 116 Mᵌ/hr

Max Powder Induction Rate: 150 lbs/min / 68 kg/min

Seal Specifications: 2 Seal Options

Ampco SBI official webpage

Ampco SBH/SBI Brochure

Mixing & Blending Processes

Performance Personified in SBH Shear Blender Series.

Ampco Applied Products offers two shear blender model series: SBH/SBI. Applications range from pharmaceutical to food, industrial to chemical … and everything in between.

These highly engineered products with critical tolerances are machined, manufactured and assembled in Glendale, Wisconsin and can be fully customized for every need. Teeth thickness, number of teeth, radius and Cartesian coordinates of the SBI blades can all be specified per customer.

For more info, contact the Pump & Valve team for full details.

All models can be customized upon request based on your specific application requirements.

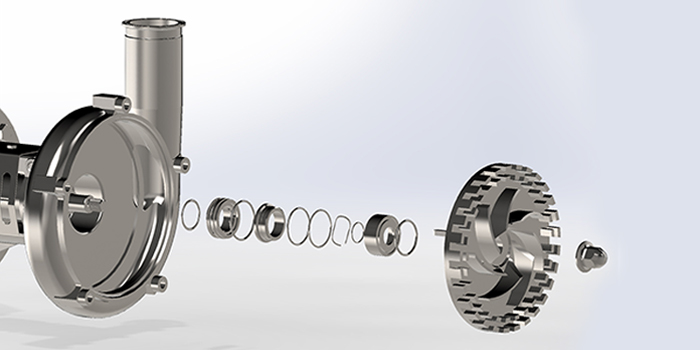

SBH High-Shear Blender

The high shear blending capability of the SBH is facilitated by the greater number and expanded rows of rectangular-shaped teeth with radial slots for the higher shear rates.

Different cover and impeller sets are available for varying application requirements. The SBH Series is based on the LF Series pump design and offers multiple front loading seal options.

SBH Advantages

Customizable

Front Loading Seal Options

Easily Converted to Double Seal in the Field

304 Stainless Steel Adapter

Manufactured and Assembled in the U.S.A.

SBH Features

Medium – High Shear Levels

316L Stainless Steel Heavy Wall Construction

Cast and Machined

304 Stainless Steel Adapter

Dynamically Balanced Impeller

316L Stainless Steel Shaft

SBH Performance Overview

Models: 6

Max Flow Rate: 200 GPM / 45 Mᵌ/hr

Seal Specifications: 2 Seal Options

Ampco SBH official webpage

Ampco SBH/SBI Brochure

Mixing & Blending Processes

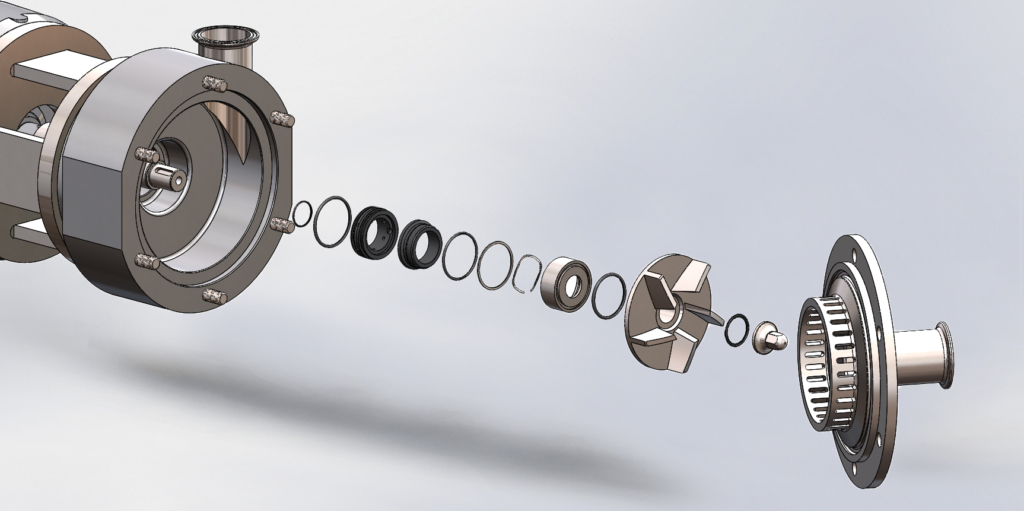

High Shear Inline Mixing with a Twist.

The ultimate in high shear mixing and dispersing, meeting the tight tolerances required in high shear applications while maintaining extremely efficient flow.

The curved wedge rotor and stator design of the SHEAR-max make it one of the most efficient and hygienic designs on the market. The SHEAR-max will disperse, dissolve, emulsify, de-agglomerate, homogenize, or simply blend.

Designed for single pass or batch style processing of liquids and semi-solids this high shear mixer is extremely effective at hydrating and dispersing powders. The innovative wedge style rotor allows solids into the shear zone while efficiently employing motor horsepower. The single or dual stage stator provides superior clean-ability and tight rotor / stator tolerances.

Machined from 316L stainless steel bar stock this mixer is built to last. Wash-down and CIP capability with optional chemical duty designs available.

SHEAR-max Advantages

Front Loading Seal Options

304 Stainless Steel Adapter

Manufactured and Assembled in the U.S.A.

SHEAR-max Features

High Shear Mixing

Single and Dual Stage Options

Pump and Blend in a Single Stage

Machined from 316L bar stock

304 Stainless Steel Adapter

Dynamically Balanced Impeller

316L Stainless Steel Shaft

Ampco SHEAR-max official webpage

Ampco SHEAR-max Brochure

Ampco SHEAR-max workhead overview

Ampco Sanitary Line Brochure

Mixing & Blending Processes