Description

Meeting Needs of the Brewing Marketplace with New Products.

As craft brewing has gained popularity, Ampco’s proven pump technology and engineering expertise have been applied to specific needs of the wine and brewing markets. It’s a strong momentum of product development with no change in site.

Every day, Ampco demonstrates its commitment to innovation and superior customer service.

Within the last several years, a number of new products have been developed to solve challenges that brewers have posed to Ampco. It’s been a great “partnership” and Ampco is proud to answer the needs.

At Ampco, engineers are encouraged to explore new product development, line extensions, and applications that can benefit from rigorous pump technology.

2015 was a particularly exciting year for Ampco Pumps with the introduction of two new products for the craft brewing industry – the ROLEC DH and the CB+. Each of these new products is designed to deliver greater efficiency, enhanced performance, and safety for brewing and dry hopping.

All Ampco craft brewing products are ideal for small to mid-size craft breweries.

Products Designed for Brewing, Wine and Cellar.

With roots in marine and industrial applications for more than 60 years, Ampco is well-versed in producing products that can withstand harsh environments and corrosive materials. It’s what drives our product excellence.

Ampco’s CB+ Craft Brew Pump was developed specifically for the craft beer industry.

Leaking pumps have been an ongoing problem for brew masters. Through the expertise of Ampco’s R&D team, a viable, long-term seal design solution was achieved to solve this nagging problem. For additional flexibility, the CB+ pump is interchangeable with Ampco’s AC and AC+ (conversion kits available).

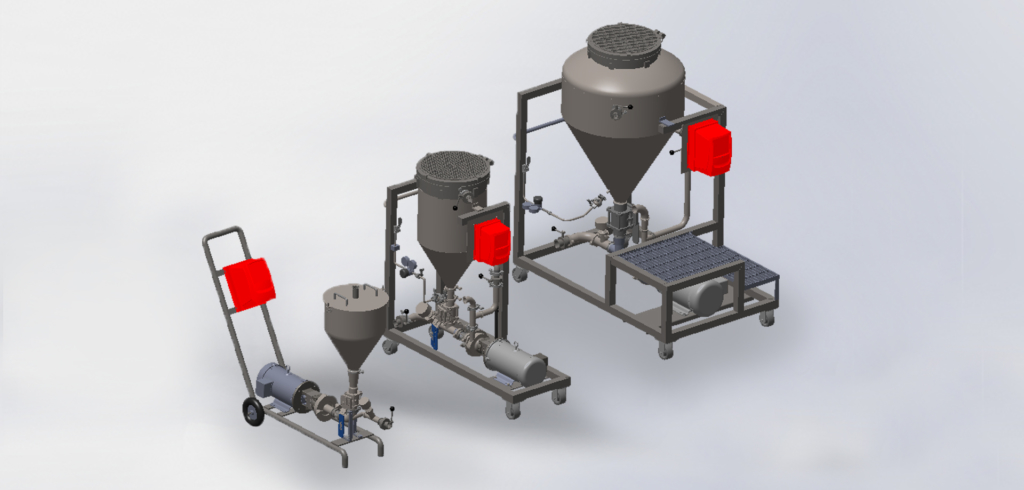

Ampco’s ROLEC DH hop induction system is a fully portable unit offering everything necessary to dry hop beer more efficiently and safely – all in one convenient unit. ROLEC DH utilizes Ampco’s leading SBI Shear Pump to simultaneously induce dry hop pellets directly into the stream of beer and recirculate the fermenter.

The Cellar Cart from Ampco is well-suited for breweries and clean-in-place (CIP) applications. Designed for maximum mobility, it’s constructed of stainless steel for durability and corrosion resistance.

Pump technology is at its best in Ampco’s Wine & Must Cart featuring the popular ZP1 positive displacement pump with its standard stainless steel gearcase. The Wine & Must Cart is used most often in wine and juice transfer, barrel work, filter feeding, and bottling and filler supply.

The ROLEC DH Provides Safe, Efficient Hop Induction.

The ROLEC DH was developed by the Ampco Applied Products division with craft brewer needs in mind. This innovative product line offering was specifically designed to help the craft beer market meet its remarkable growth potential.

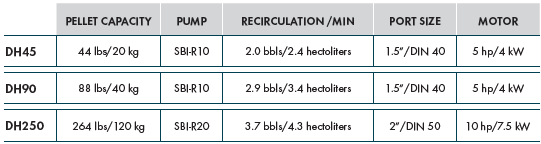

The ROLEC DH45, ROLEC DH90 and ROLEC DH250 models offer small to large scale breweries a safe and efficient way to dry hop and creatively induce flavors into beer.

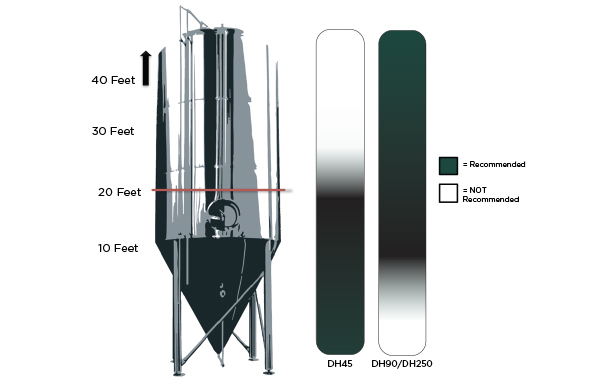

The ROLEC line eliminates breweries safety concerns of dry hopping on a ladder at the top of a two-story fermenting tank. These fully portable DH systems powered by Ampco’s in-line SBI shear blending pump are used at ground level.

The SBI pump recirculates the fermenter while inducing dry hops and other induced media directly into the stream of beer; all from an oxygen free environment.

The DH90 and DH250 are built with a pressurized carbon dioxide chamber to mitigate oxygen intrusion. The DH45 is a smaller scale version offering a non-pressurized vessel utilizing a “blanket” of CO₂ to protect the product from oxygen intrusion. The DH45 is capable of induction on fermenters with a maximum height of 20 feet and can be used additionally as transfer and CIP pumps.

The ROLEC DH units are not just for hop induction, they can be utilized to induce fruit, coffee, spices, nuts, honey, maple syrup and more – the induction options are limited only by the brewers creativity.

Each Ampco Applied Products DH unit is delivered ready to go as a fully self-contained portable unit. VFD controls are in place. The sanitary DH90 and DH250 are CIP-able with no additional CIP pump required.

The ROLEC dry hopping process maximizes pellet dispersion, flavor, and aroma. The increased surface area and forced contact produces dry hopped beer more efficiently than conventional methods – resulting in decreased tank-time and in many cases greater yield.

Other application opportunities include spices, coffee, lupulin biofine, fruit puree, sugar, cocoa nibs, and chocolate. Contact Ampco today to determine which model fits your brewery best.

What the Brewers Say…

Ampco Applied Products’ ROLEC DH is being embraced around the world and are currently installed in breweries from New York to Australia.

“The AMPCO DH250 easily interfaces with our existing automation in place for our Mueller 725 bbl fermentation vessels, which has increased our breweries’ pellet brand capacity. Skid use is straightforward and safe, with a significant reduction in total time required for T90 pellet dosing as compared to our previous methodology. Sensory panel validation shows that dry hop quality with AMPCO use meets current brand standard, while GCMS indicates improved efficiency with higher levels of Myrcene and Linalool present in the final product.” – S.G. Assistant Brewmaster, Cellar – Deschutes Brewery

“With our graded floors, this unit made dry hopping much safer than with our scissor lift. We had a very noticeable increase in hop aroma from circulating with this unit too! Our DO sensor picked up no more O2 than normal.” – Midwest Craft Brewer

ROLEC DH Series Advantages

Contains Everything Needed for Hop Induction

Fully Portable

Greater Hop Yield

Improved Flavor and Aroma

VFD Included

Base Material 304 Stainless Steel

Wetted Part 316L Stainless Steel

Manufactured and Assembled in U.S.A.

ROLEC DH Series

SBI Powered Dry Hop System Features

304 Stainless Steel Base Material

316L Wetted Parts

All Models Include VFD (NEMA4X Standard)

Stainless Steel / Polyurethane Casters

DH45/ DH90 / DH250 are Fully CIP-Able with No Additional CIP Pump Required

Standard 50’/15m Cord

ROLEC DH Series Performance Overview

SBI-R00: Affordable Portable Fermenter Recirculation

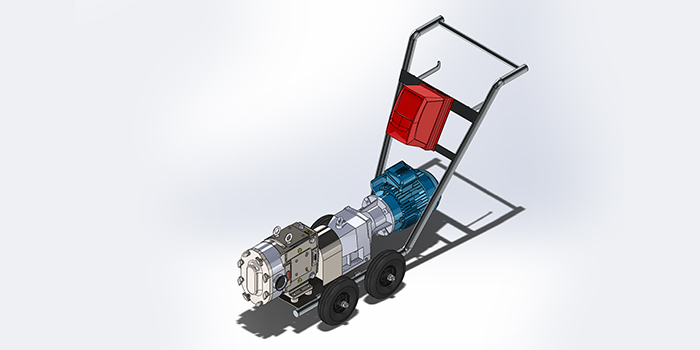

The SBI-R00 is a unique and portable hop blending unit for fermenter recirculation with tremendous advantages over conventional cellar carts. Small scale brewers now have the ability to improve hop yield and increase surface area.

The SBI-R00 chops hop pellets while simultaneously recirculating the fermenter. The process uses a 1.5HP motor and VFD which can be operated using 115V single phase power.

Based on tremendous market response to the ROLEC DH 45/90/250 dry hop systems, the SBI-R00 was developed to make it possible for small batch brewers to enjoy many of the same benefits realized with the larger systems including decreased tank time, improved flavor profile and increased shelf life.

SBI-R00 Advantages

1.5 HP 3500 RPM Motor

Available Voltages – 115V, 208V, 230V, 460V, 575V

Up to 40 GPM / 9 m³/ hr or 1.3 bbls / min Recirculation Rate

Up to 50 ft head / 22 psi / 1.5 BAR

NEMA 4X VFD

Input Cord Available

Stainless Steel Two Wheel Cart

Can Be Used as Cellar Pump

Manufactured and Assembled in U.S.A.

Ampco ROLEC DH Official Webpage

Ampco ROLEC DH Series Brochure

CB+ Craft Brew Pump is Engineered for Craft Brewery Efficiency.

Ampco’s CB+ Craft Brew Pump was developed specifically for the craft brewing industry to allow brewers to focus on creating their next signature beer rather than deal with leaking pumps.

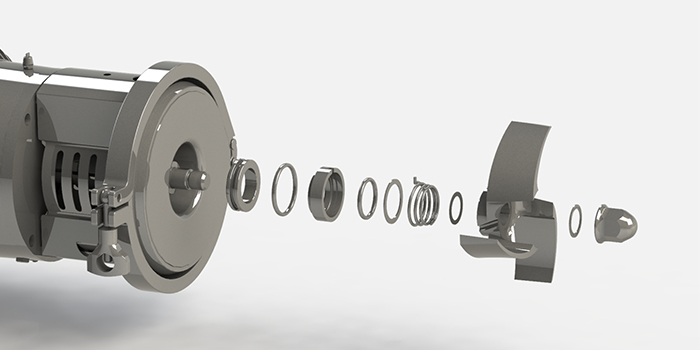

The CB+ features an internal seal design that reduces product build-up and leaking. When pumping wort at temperatures near boiling, flashing is likely to occur… which can cause premature seal failure.

The CB+ minimizes seal problems in several ways:

The internal seal is submersed in the product to promote cooling,

When the pressure within the pump rises it creates a higher closing force on seal faces to minimize product buildup, and

An internal spring agitates wort solids to avoid pooling on seal faces.

The CB+ Pump is dimensionally and hydraulically interchangeable with the AC, AC+, and competitor C Series pumps.

The CB+ is also available in 8 model sizes, contact us to see how the CB+ can benefit your brewing process.

Pumps in Action:

“We recently installed a couple of CB+ seal conversion kits from Ampco Pumps on our Kettle and Mash Tun pumps. Once Ampco Pumps knew of the problem with the old seals, they provided this new seal system to us as soon as they could and kept us up-to-date on the status of the replacement.

The seals have been running leak free for several months now – which has been awesome since the old seals would leak within 1 to 2 weeks.”

Josh West,

Lone Tree Brewing Company

CB+ Pump Advantages

Low Cost

316L Stainless Steel Construction

304 Stainless Steel Adapter

Cleaner Seal Design

Dimensionally and Hydraulically Interchangeable with Competing Pumps

Manufactured and Assembled in the U.S.A.

CB+ Series Centrifugal Craft Brew Pump Features

316L Stainless Steel

304 Stainless Steel Adapter

Dynamically Balanced Impeller

316L Stainless Steel Shaft

CB+ Series Performance Overview

Models: 10

Max Discharge Pressure: 130 PSI / 9 BAR

Max Flow Rate: 920 GPM / 209 Mᵌ/ hr

Max Viscosity: 1,200 cP

Seal Specifications: 1 Seal Options

Conversion Kits are Available:

CB+1 Conversion Kit: AC+ to CB+ with a simple seal and back-plate replacement.

CB+2 Conversion Kit: Converts AC and competing C Series pumps to CB+ by replacing the seal, back-plate, stub shaft, collar, O-ring, and impeller nut.

Ampco CB+ Craft Brew Pumps Official Webpage

Ampco CB+ Craft Brew Series Brochure

Portable Sanitary Centrifugal Technology at Work in Cellar Cart.

The Ampco Cellar Cart is most commonly used as a transfer pump or portable CIP pump. It’s lightweight and designed to provide users with maximum mobility in cramped cellars.

This robust 2-wheeled cart, features a corrosion-free 304 stainless steel frame, polypropylene wheels, and NEMA 4X VFD. Carts come in two standard models, equipped with the popular Ampco AC+ pump.

The Ampco AC+ pump featured on the Cellar Cart is built of 316L stainless steel and includes a 304 stainless steel adapter, making this centrifugal workhorse nearly corrosion free. The AC+ engineered innovations include a threaded stub shaft with acorn nut and shaft collar – ensuring a more balanced and stable pump performance leading to increased seal life.

An optional CB+ seal is available for carted pumps focused on whirlpool or knockout. This internal seal has been specifically designed for craft brewers to promote cooling and further enhanced seal longevity. See CB+ Craft Brew Pump product tab above for additional information.

The Cellar Cart for Beer & CIP can be customized to include any of Ampco’s positive displacement pumps, shear blenders, and more.

Cellar Cart Advantages

304 Stainless Steel Adapter

Enhanced AC+ Shaft Design

Customizable

Manufactured and Assembled in the U.S.A.

Cellar Cart Features

Ampco AC+ Series Pump

316L Stainless Steel Construction

304 Stainless Steel Adapter

Dynamically Balanced Impeller

316L Stainless Steel Shaft

NEMA 4X VFD

Polypropylene Wheels

Cellar Cart Performance Overview

Models: 2 (Additional Pump Sizes are Available)

Max Discharge Pressure: 60 PSI / 4 BAR

Max Flow Rate: 920 GPM / 209 Mᵌ/ hr

Max Viscosity: 1,200 cP

Seal Specifications: 4 Seal Options

Ampco Cellar Cart Official Webpage

Ampco Cellar Cart Brochure

Ampco Sanitary Line Brochure

Wine & Must Cart Delivers Portable Transfer Technology.

Ampco’s Wine & Must Cart comes equipped with the durable Ampco ZP1 Series positive displacement pump.

Wine & Must Carts are available in four standard model sizes and are used for applications including wine and juice transfer, barrel work, filter, filling, and bottling supply.

Built to withstand harsh working environments – inside and out – the Ampco Wine and Must Cart can stand up to whatever the application.

Options are available for each model – contact our team to discuss your specific application requirements.

No longer will you need to worry about rusted gearcases, this workhorse comes with a 304 stainless steel gearcase (like all Ampco PD pumps).

Wine Cart Advantages

304 Stainless Steel Gearcase

17-4ph Shafts – More than 3 Times the Yield Strength of 316

Customizable

Durable, Completely Stainless Steel Construction

Stainless Steel Bearing Retainers

Manufactured and assembled in the U.S.A.

Wine & Must Cart Features

Ampco ZP1 Positive Displacement Pump

NEMA 4X VFD

304 Stainless Steel Gearcase

316L Stainless Steel Wetted Parts

Alloy 88 Non-Galling Rotors

17-4ph Stainless Steel Shaft

Helical Gears

304 Stainless Steel Portable Cart

10” Foam Filled Wheels

Wine & Must Cart Performance Overview

Models: 4

Max Discharge Pressure: 225 PSI / 15.5 BAR

Max Flow Rate: 452 GPM / 103 Mᵌ/hr

Max Viscosity: 1mil cP

Seal Specifications: 4 Seal Options

Ampco Wine & Must Cart Official Webpage

Ampco Wine & Must Cart Brochure